Offline coated glass is glass that is specially coated using a vacuum magnetron sputtering coating production line after the flat glass leaves the factory. This type of glass achieves low-emission (Low-E) function by coating a multi-layer composite film on the glass surface, and has many significant advantages.

The film thickness can accurately control light, and can be made into a multi-layer optical interference film system, which can selectively control the solar spectrum that passes through the film layer, and achieve precise control of visible light, infrared light, etc., to meet the lighting needs of different scenes. For example, in commercial buildings, it can block excessive solar radiation heat from entering the room, reduce air conditioning energy consumption, and ensure sufficient natural lighting indoors.

Application :

Building systems/ Automotive systemsOrder(MOQ) :

15 containersCertification :

ISO9001、 ISO14001、ISO45001、ISO50001、AS/NZS2208、AS4666Payment :

T/T. L/CShipping Port :

Fuzhou FujianProduct Origin :

ChinaTechnical strength

The core key equipment comes from Germany, the United States, and Japan.

The world's first float glass production line is intelligently connected.

Self-produced high-quality float glass raw sheets.

We can produce over 60 types of film products including single, double, and triple silver.

Global leading process technology, small batch color difference, uniform color, strong processability.

Product Parameters

| Thickness | 2~19mm |

| Minimum Size | 400mm x 600mm |

| Regular Size | 2134mmx3300mm |

| Maximum Size | 2880mm x 150000mm |

Production line and equipment situation

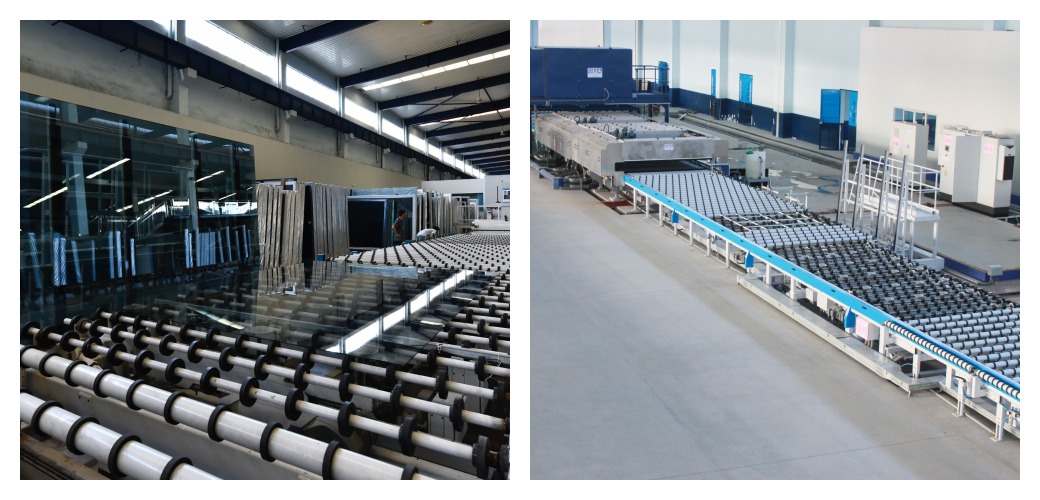

1.Low-E Coating Production Line

In November 2020, we introduced an offline coating glass production line with international advanced level, combined with high-performance float glass substrates and an innovative production mode, making the Xinfuxing Glass brand renowned in the national market and firmly establishing its market position as the "preferred brand of Chinese architectural glass".

2.Equipment Introduction

The three silver coated glass production line is about 315 meters long and divided into four functional sections: upper film, cleaning, coating, and lower film. The vacuum key film section is 145 meters long and equipped with 53 cathodes, which is in a leading position in the industry in terms of cathode quantity. The biggest advantage of this production line is that it is connected to the float glass line for production, achieving maximum production capacity and efficiency.

3.Technical advantages

· Target material positions: 62 (with the highest number of cathode and target material positions in domestic coating lines)

· Maximum production cycle time: 22 seconds per piece (the fastest production cycle time for domestic coating lines)

· Production board surface: The original production specifications are relatively large (among the top 3 in China)

· Production line layout: Connected production with high-quality float glass line (world's first)

· Membrane coverage: It can produce over 60 types of high, medium, and low transmittance solar films, as well as single silver/double silver/triple silver Low-E film systems, with a wide range of varieties.

4.Processing range

2~19 mm; Standard specifications: 2800 mmx4880 mm; Ultra long mode: 2800mm x 15000mm;

5.Production capacity and output

Production cycle -22 seconds/piece for single silver products, 30 seconds/piece for double silver products, and 60 seconds/piece for triple silver products, with an annual production capacity of up to 20 million square meters.

Product Line

Product classification

Single silver Low-E glass

Double silver Low-E glass

Three silver Low-E glass:

Sunshine film glass

Tags :